DIN259 Thread 2" Brass Spring Check Valves Female X Female

Description

Basic Info

| Model NO. | YSDBCV006 |

| Flow Direction | Unidirection |

| Application | Water Industrial Usage, Household Usage |

| Thread Connection | Female Thread, Bsp.NPT |

| Working Pressure | Pn25 |

| Technical | Casting |

| Certificate | ISO9001, CE, Acs.UL |

| Standard or Nonstardard | Standard |

| Transport Package | Polybag, Inner Box, Carton and Wooden Pallets |

| Specification | 1/2"--4" |

| Trademark | xbfm/ OEM |

| Origin | Zhejiang |

| HS Code | 8481804090 |

| Production Capacity | 10 0000PCS Per Month |

Product Description

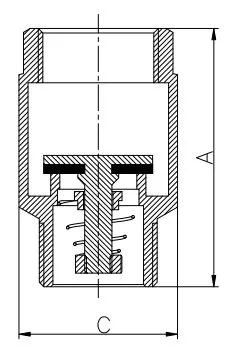

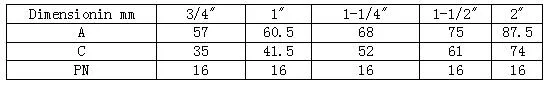

DIN259 Thread 2" Female X Female Brass Spring Check Valves

Specifications

| ITEM: | Brass Spring Check Valve | SIZE: | 3/4" - 2" |

|---|---|---|---|

| BRASS MATERIAL: | HPb 57-3 | CONNECTION TYPE: | Female X Female |

| WORKING PRESSURE:: | 16 Bar(232 Psi) | THREAD: | ISO228 (equivalent To DIN 259 And BS2779) |

| WORKING TEMPERATURE: | From -10 ºC To +120 ºC (from 14ºF To 248ºF) | HIGH LIGHT: | DIN259 Brass Spring Check Valves,BS 2779 Brass Spring Check Valves ,DIN259 Non Return Valve Spring Type |

| High Light: | 2" Brass Spring Check Valves ,DIN259 Brass Spring Check Valves ,DIN259 2 brass check valves | ||

DIN259 Thread 2" Female X Female Brass Spring Check Valves

- Description

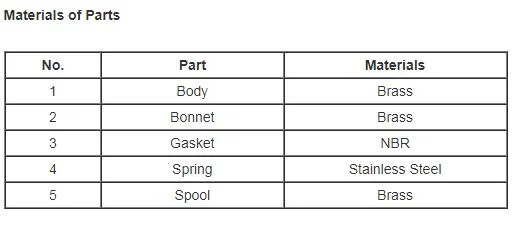

- Details

Brass Bonnet: High-density forging, no blister, no air holes, no leakage. Made by special high precision CNC machines.

Brass Valve Spool: High-density forging, no blister, no air holes, no leakage. Made by special high precision CNC machines.

Rubber Washer: Made of imported raw material, long service life and not easy to leak.

Spring: Made of imported raw material, stable performance, good sealing, and not easy to leak.

- Technical Specification

- Full flow Female x Male brass spring check valves.

- The thread, materials, etc. can be customized.

Why Choose US

We control the material of PTFE(Tef lon) and stainless steel wires per customer's request.

Some are from Japan and Taiwan, some are from China local. Only choose high quality material.

We test leakage of each roll before braiding, then we cut 300mm and crimp it to test

burst pressure after brading.

We use CNC Lathes Machine for end fittings production. Machine system, knife and inspection

tools are all imported from Japan.

We use Techmaflex Crimping Machine which is imported from France. This machine has

accurate and stable performance for crimping because it is produced for PTFE hose crimping only.

Welcome to your warmly inquiry!We would like to service with you!!

Customer designs are also welcomed!!

Prev: High Quality Brass Material Manifold Body (HM05)

Next: Male Thread Straight Brass Male Side Connection Manifold

Our Contact