Prv Diaphragm Microfilter Hydraulic Pilot Holding Control Pressure Reducing Valve Prices

Description

Basic Info

| Model NO. | LK-S16 |

| Connection | Flange |

| Valve Seat | Single-Seat |

| Structure | Diaphragm |

| Material | Cast Iron |

| Standard or Nonstandard | Standard |

| Product Name | Pressure Reducing Valve |

| Body | Ductile Iron |

| Allen Bolts | Carbonization Process |

| Seals | NBR, EPDM |

| Bonnet | Gray Irorn, Ductile Iron, Cast Steel |

| Stem | Ductile Iron |

| O-Ring Seals | NBR |

| Bolt | Carbon Steel, Alloy Steel |

| Recyclable Part | Valve Body/Stem/Seat |

| Transport Package | Wooden Case |

| Specification | 8 in |

| Trademark | LIKE |

| Origin | China |

| HS Code | 8481804090 |

| Production Capacity | 1000000 |

Packaging & Delivery

Package size per unit product 60.00cm * 50.00cm * 40.00cm Gross weight per unit product 20.000kgProduct Description

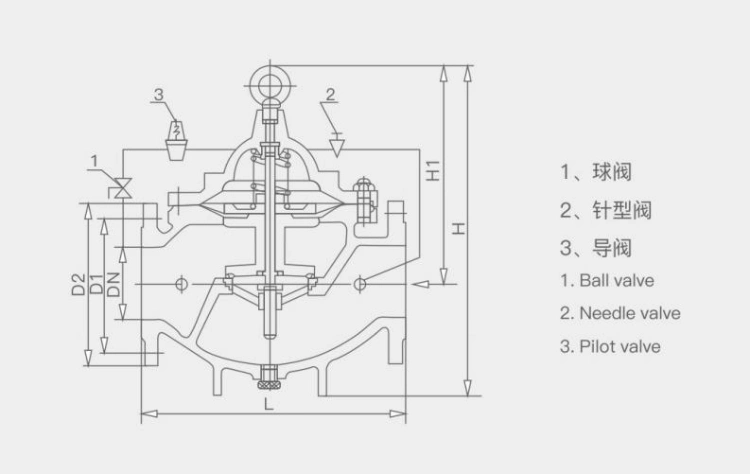

PRV Diaphragm Type Hydraulic Pressure Reducing Valve Pilot Valve with Microfilter

The valve is used for domestic water supply, fire water supply and other industrial water supply systems. The outlet pressure of the

main valve can be adjusted by adjusting the pressure reducing pilot valve.

The outlet pressure does not change with the change of inlet pressure and inlet flow. The outlet pressure can be maintained at the

set value safely and reliably, and the set value can be adjusted according to the need to achieve the purpose of decompression.

The valve has the advantages of accurate pressure reduction, stable performance, safety and reliability, convenient installation

and adjustment, and long service life.

Meterial of main parts

| Part name | Meterial |

| Body | Gray iron, ductile iron, cast steel |

| Gate | Ductile iron+EPDM or NBR |

| Allen bolits | Carbonization process |

| Seals | NBR,EPDM |

| Bonnect | Gray iron,ductile iron,cast steel |

| Stem | Stainless steel |

| O-ring seals | NBR |

| Thrust bearings | Tin bronze |

| Bolt | Carbon steel,ally steel |

| Gland | Ductile iron,cast steel |

| Dust Cover | NBR |

| Hand wheel | Malleable iron |

Main connecting dimensions of pressure reducing and stabilizing valve

| (DN) | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 700 | 800 | |

| L | PN1.0MPa | 241 | 234 | 280 | 360 | 430 | 455 | 585 | 790 | 900 | 900 | 962 | 962 | 1076 | 1232 | 1437 | 1750 |

| PN1.6MPa | 241 | 234 | 280 | 360 | 430 | 455 | 587 | 794 | 900 | 900 | 962 | 962 | 1076 | 1232 | 1437 | 1750 | |

| H1 | 152 | 145 | 167 | 232 | 288 | 342 | 413 | 502 | 600 | 600 | 685 | 685 | 880 | 1050 | 1225 | 1400 | |

| H | 250 | 250 | 271 | 375 | 455 | 502 | 636 | 781 | 913 | 913 | 1035 | 1035 | 1300 | 1535 | 1793 | 2022 | |

Qualification certificate

FAQ1. Can I have a trial sample order?

A: Definitely Yes.We welcome sample order to test and check quality.

2. Can OEM or ODM be provided?

A:Yes, we have a great research & development team. The products can be made according to your request.3. Can you provide the relevant documentation and certificate?

A:Yes, we can provide you with the documents like catalogue and ACD drawing. And certificate you need ,ISO9001, ISO14001, OHSAS18001, TS, API, CE, RoHS, CCC certificates.

4. Why choose us?

A:1. excellent quality and competitive price: Like Valve have have the most advanced machining equipment, and strictly follow the ISO9000 standard production management

2. Strict testing system: raw material, dimension and pressure test PIECE BY PIECE before shipment.

3. Experienced research and producing team with more than 20 years, can Solve your confusion and problems professionally. We have cooperated with the customers all over the world more than 60 countries and regions

4. 12 months after-sales Services: any problems and feedbacks will be answered intime.5. What is your terms of delivery and payment?

A: We accept EXW, FCA, FOB, CFR, CIF,etc. You can choose WHATEVER YOU NEED.

T/T, LC, alibaba pay, MIC etc.

6.What's the package and how do you ship the goods?

A: Usually with standard plywood case of 1.1*1.1*1.1m shipped by sea. But Airline shipping is also optional.7. What is the average lead time?

A: For samples, the delivery time is within one week. For bulk order, the lead time is about 15-60 days after receiving the deposit payment. we can provide production schedule and related photos every two weeks if you need.

Our Contact